The Science Behind Amorphous Nanocrystalline Inductors

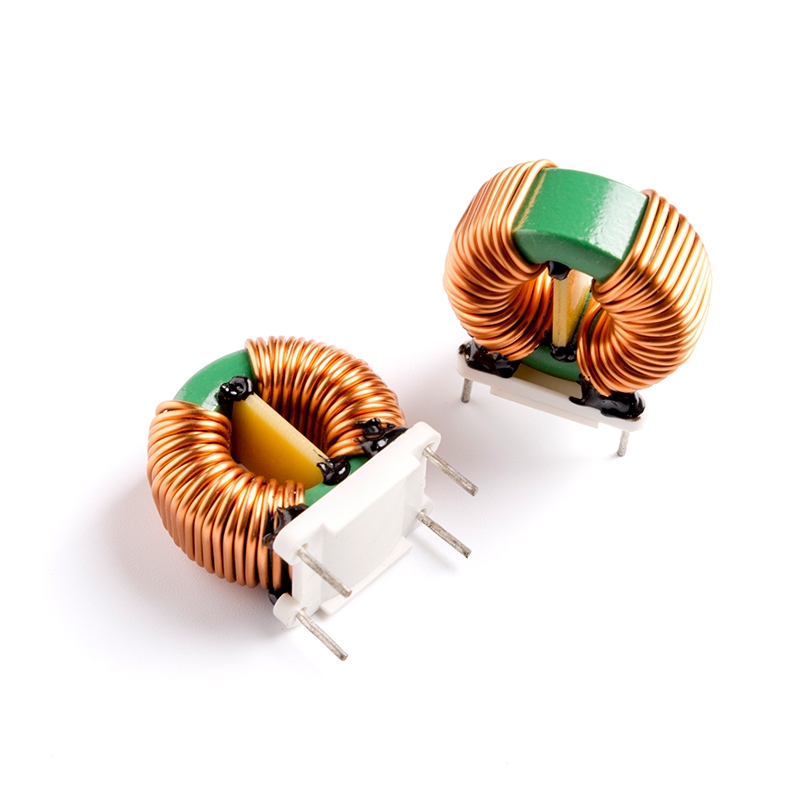

To truly understand the potential of amorphous nanocrystalline inductors, it’s important to first explore what sets them apart from traditional inductors. At their core, these inductors use an amorphous alloy (meaning a metal without a distinct crystalline structure) that combines iron with other metals such as silicon and boron. This unique alloy composition gives the material excellent magnetic properties, enabling high efficiency even at higher frequencies.

The "nanocrystalline" aspect refers to the fact that the material is composed of extremely small, fine magnetic grains—typically on the scale of nanometers. These nanocrystals are carefully engineered to optimize the material's magnetic behavior, resulting in significantly improved performance compared to conventional magnetic cores, which are typically made of ferrite or laminated iron.

Key Benefits of Amorphous Nanocrystalline Inductors

Higher Efficiency

One of the standout features of amorphous nanocrystalline inductors is their energy efficiency. Due to the absence of crystalline boundaries, these inductors suffer from much lower core losses, which typically arise from eddy currents and hysteresis in traditional magnetic materials. This allows them to operate more efficiently, especially at high frequencies, which is crucial in modern electronics that require compact, high-performance components.

Compactness and Light Weight

With efficiency at a premium, the size of these inductors can be dramatically reduced. This is especially valuable in industries like consumer electronics, where space is limited, and every millimeter counts. Smartphones, laptops, and wearable devices can all benefit from the space-saving capabilities of these high-performance inductors.

Wide Frequency Range

Amorphous nanocrystalline materials are known for their ability to operate efficiently across a broad range of frequencies. Whether it’s for low-frequency power supply circuits or high-frequency signal processing, these inductors offer versatility and superior performance in applications that demand high-frequency operation.

Thermal Stability

Another important benefit of these inductors is their thermal stability. They are less susceptible to performance degradation due to temperature changes compared to traditional magnetic materials. This characteristic makes them suitable for automotive and industrial applications where devices are exposed to extreme temperatures and harsh environments.

Reduced Size and Weight

As the size and weight of electronic devices continue to shrink, the need for smaller components without compromising on performance becomes even more pressing. Amorphous nanocrystalline inductors enable such advancements, providing manufacturers with the ability to produce slimmer devices without losing out on the power capabilities needed for modern electronics.

Where Are Amorphous Nanocrystalline Inductors Used?

Thanks to their superior performance, amorphous nanocrystalline inductors have found a wide range of applications across different industries:

Power Electronics: In power converters and transformers, these inductors are highly effective at improving power conversion efficiency and reducing energy loss, especially in high-frequency applications.

Automotive Electronics: With the rise of electric vehicles and the increasing demand for electric powertrains, these inductors offer excellent energy efficiency for power supply systems in electric vehicles and hybrid systems.

Telecommunications: In communication devices, these inductors play a crucial role in signal processing, helping to ensure the stability and quality of signals.

Renewable Energy Systems: As the world turns toward solar and wind energy, efficient energy storage and conversion systems are needed. Amorphous nanocrystalline inductors are well-suited for use in inverters, energy storage systems, and wind turbines.

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>