Amorphous nanocrystalline inductors represent a significant advancement in the field of electronics, particularly in power management and signal processing applications. These inductors, composed of a unique blend of amorphous and nanocrystalline materials, offer enhanced performance characteristics compared to traditional inductors. This article delves into their construction, benefits, applications, and considerations for use in various industrial contexts.

Construction and Composition

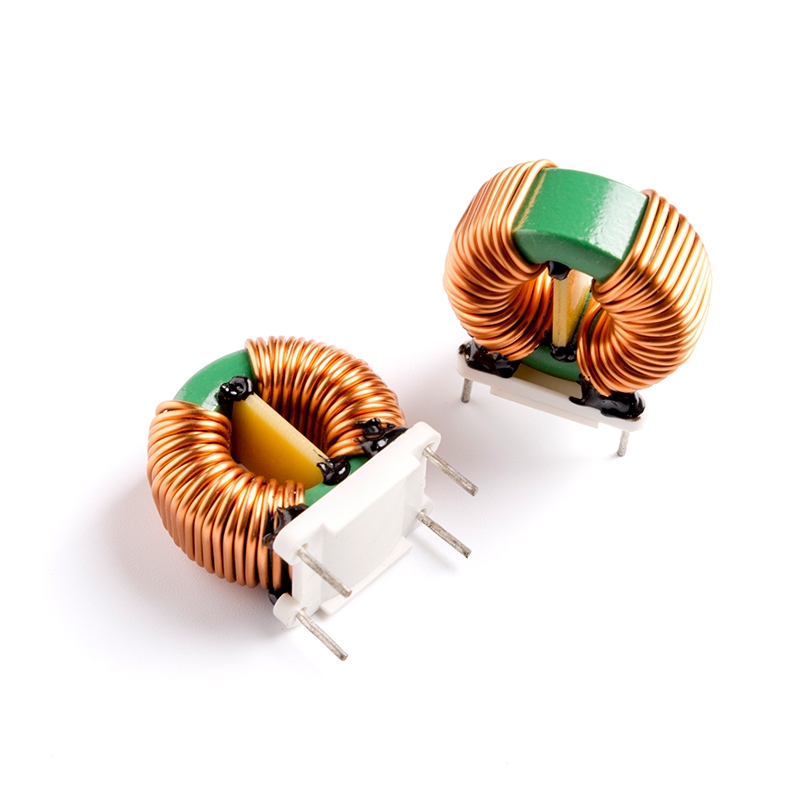

Amorphous nanocrystalline inductors are made from metal alloys that exhibit a non-crystalline structure at the atomic level. Common materials include iron, cobalt, and nickel, which are processed into thin strips or cores. The manufacturing process often involves rapid cooling techniques that prevent the formation of a crystalline structure, resulting in enhanced magnetic properties. The nanocrystalline structure is achieved through controlled heat treatment, creating a network of small, crystallized grains within the amorphous matrix.

Key Benefits

High Magnetic Permeability: Amorphous nanocrystalline inductors possess exceptionally high magnetic permeability, allowing for greater efficiency in magnetic flux conduction. This results in lower core losses and improved energy efficiency.

Lower Core Losses: These inductors demonstrate significantly reduced hysteresis and eddy current losses compared to traditional ferrite or silicon steel inductors. This characteristic makes them ideal for high-frequency applications, reducing heat generation and improving reliability.

Compact Size: Due to their high performance, amorphous nanocrystalline inductors can be designed in smaller packages without sacrificing functionality. This compactness is particularly advantageous in modern electronics where space is at a premium.

Temperature Stability: These inductors maintain stable performance across a wide temperature range, making them suitable for use in various environments, from industrial settings to consumer electronics.

Applications

Amorphous nanocrystalline inductors find applications across multiple industries, including:

Power Electronics: They are widely used in switch-mode power supplies (SMPS) and voltage regulators, where high efficiency and compactness are critical. Their ability to handle high-frequency signals makes them ideal for these applications.

Electric Vehicles (EVs): In EVs, these inductors are used in battery management systems and motor drives, contributing to improved energy efficiency and performance.

Telecommunications: The high-frequency performance of amorphous nanocrystalline inductors makes them suitable for RF applications, including filters and transformers in communication devices.

Renewable Energy: They play a crucial role in energy conversion systems, such as inverters for solar and wind energy systems, where efficiency is paramount.

Considerations for Use

When integrating amorphous nanocrystalline inductors into designs, several factors should be considered:

Cost: While these inductors offer enhanced performance, their manufacturing process can lead to higher costs compared to conventional inductors. Designers must evaluate the cost-to-benefit ratio for their specific applications.

Design Compatibility: Ensuring compatibility with existing circuit designs is crucial. Amorphous nanocrystalline inductors may require adjustments in circuit layout or component selection.

Saturation Current: Each inductor has a specified saturation current limit. Exceeding this limit can lead to a decrease in inductance and potential damage. It’s vital to consider this parameter during design.

English

English 中文简体

中文简体 Deutsch

Deutsch 日本語

日本語

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>